Xaiv rau: Dual-clutch gearbox khoom yog ntub ob-clutch gearbox, lub plhaub txhawb nqa muaj clutch thiab gearbox plhaub, ob lub plhaub tsim los ntawm kev kub siab casting txoj kev, nyob rau hauv cov txheej txheem ntawm cov khoom tsim thiab ntau lawm tau ntsib ib tug nyuaj txoj kev txhim kho. , qhov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob.

ntub ob-clutch kis tau tus mob, uas siv ib tug tshiab cascade iav teeb, ib tug electro-mechanical hloov tsav system thiab ib tug tshiab electro-hydraulic clutch actuator. Lub plhaub dawb paug yog ua los ntawm kev kub siab casting aluminium alloy, uas muaj cov yam ntxwv ntawm lub teeb yuag thiab lub zog siab. Muaj hydraulic twj tso kua mis, lubricating kua, txias yeeb nkab thiab sab nraud cua txias system nyob rau hauv lub gearbox, uas tso rau pem hauv ntej cov kev xav tau ntau dua ntawm kev ua tau zoo txhua yam thiab sealing kev ua tau zoo ntawm lub plhaub. Daim ntawv no piav qhia yuav ua li cas los daws cov teeb meem zoo xws li lub plhaub deformation, lub qhov cua shrinkage thiab cov pa xa tawm uas cuam tshuam rau tus nqi dhau heev.

1,Kev daws teeb meem deformation

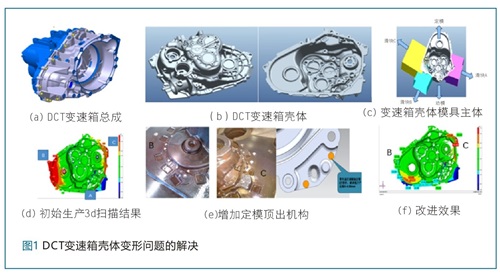

Daim duab 1 (a) hauv qab no, Lub gearbox yog tsim los ntawm high-pressure cam khwb cia txhuas alloy gearbox vaj tse thiab ib tug clutch vaj tse. Cov khoom siv yog ADC12, thiab nws cov phab ntsa tuab yog li 3.5 hli. Lub plhaub gearbox yog qhia hauv daim duab 1 (b). Qhov loj me yog 485mm (ntev) × 370mm (dav) × 212mm (qhov siab), qhov ntim yog 2481.5mm3, qhov projected cheeb tsam yog 134903mm2, thiab qhov hnyav yog li 6.7kg. Nws yog ib feem nyias-walled tob-cav. Xav txog kev tsim thiab kev siv tshuab ntawm cov pwm, kev ntseeg siab ntawm cov khoom molding thiab cov txheej txheem ntau lawm, pwm yog teem raws li qhia nyob rau hauv daim duab 1 (c), uas yog tsim los ntawm peb pawg sliders, txav pwm (nyob rau hauv cov kev taw qhia ntawm lub sab nrauv kab noj hniav) thiab tsau pwm (nyob rau hauv cov kev taw qhia ntawm lub puab kab noj hniav), thiab lub thermal shrinkage tus nqi ntawm lub casting yog tsim los rau 1.0055%.

Tiag tiag, nyob rau hauv tus txheej txheem ntawm kev kuaj thawj zaug tuag casting, nws tau pom tias txoj haujlwm loj ntawm cov khoom tsim los ntawm kev tuag casting yog qhov txawv ntawm cov qauv tsim (qee txoj haujlwm tau tshaj 30% tawm), tab sis cov pwm loj yog tsim nyog thiab shrinkage tus nqi piv nrog qhov tseeb qhov loj kuj yog raws li txoj cai shrinkage. Txhawm rau kom paub qhov ua rau ntawm qhov teeb meem, 3D scanning ntawm lub cev lub plhaub thiab theoretical 3D tau siv rau kev sib piv thiab kev tsom xam, raws li qhia hauv daim duab 1 (d). Nws tau pom tias lub hauv paus positioning cheeb tsam ntawm qhov dawb paug yog deformed, thiab tus nqi deformation yog 2.39mm nyob rau hauv cheeb tsam B thiab 0.74mm nyob rau hauv cheeb tsam C. Vim hais tias cov khoom yog raws li lub convex point ntawm dawb paug A, B, C rau tom ntej ua qhov ntsuas qhov ntsuas qhov ntsuas thiab ntsuas ntsuas, qhov deformation ua rau hauv qhov ntsuas, lwm qhov loj me rau A, B, C raws li lub hauv paus ntawm lub dav hlau, txoj hauj lwm ntawm lub qhov yog tawm ntawm kev txiav txim.

Kev tshuaj xyuas ntawm cov laj thawj ntawm qhov teeb meem no:

① Kev kub siab casting tuag tsim txoj cai yog ib qho ntawm cov khoom tom qab demoulding, muab cov duab rau cov khoom ntawm tus qauv dynamic, uas yuav tsum tau cov nyhuv ntawm cov qauv dynamic ntawm pob quab yuam yog ntau dua li cov rog ua rau lub hnab ntim ruaj khov, vim yog qhov sib sib zog nqus kab noj hniav tshwj xeeb cov khoom nyob rau tib lub sij hawm, sib sib zog nqus kab noj hniav nyob rau hauv lub cores nyob rau hauv tas li pwm thiab sab nraud kab noj hniav tsim nto ntawm lub txav pwm cov khoom los txiav txim cov kev taw qhia ntawm pwm parting thaum yuav inevitably raug kev txom nyem traction;

② Muaj cov sliders nyob rau sab laug, qis thiab txoj cai ntawm cov pwm, uas ua lub luag haujlwm pabcuam hauv clamping ua ntej demould. Qhov tsawg kawg nkaus txhawb zog yog nyob rau sab sauv B, thiab tag nrho cov nyiam yog concave nyob rau hauv kab noj hniav thaum lub sij hawm thermal shrinkage. Ob qho laj thawj saum toj no ua rau qhov loj tshaj plaws deformation ntawm B, ua raws li C.

Lub tswv yim txhim kho los daws qhov teeb meem no yog ntxiv ib qho kev ruaj khov ejection mechanism Daim duab 1 (e) ntawm qhov chaw tuag tas. Thaum B nce 6 teeb pwm plunger, ntxiv ob lub pwm ruaj khov plunger hauv C, cov pas nrig ruaj khov yog tso siab rau qhov pib dua siab, thaum txav pwm clamping dav hlau teeb tsa lub zog pib nias rau hauv pwm, pwm tsis siv neeg tuag siab ploj, sab nraub qaum. ntawm lub phaj caij nplooj ntoos hlav thiab tom qab ntawd thawb lub ncov saum toj kawg nkaus, coj txoj kev txhawb nqa cov khoom tawm los ntawm cov pwm ruaj khov, thiaj li ua kom paub qhov txawv ntawm qhov demoulding deformation.

Tom qab kev hloov pauv pwm, qhov demoulding deformation raug txo kom tiav. Raws li pom nyob rau hauv FIG.1 (f), qhov deformations ntawm B thiab C yog tswj tau zoo. Point B yog +0.22mm thiab point C yog +0.12, uas ua tau raws li qhov yuav tsum tau ntawm qhov khoob contour ntawm 0.7mm thiab ua tiav ntau lawm.

2 、 Kev daws teeb meem ntawm lub plhaub shrinkage qhov thiab to

Raws li paub rau txhua tus, kev kub siab casting yog ib txoj hauv kev uas cov kua hlau tau nrawm nrawm rau hauv cov hlau pwm kab noj hniav los ntawm kev siv qee qhov siab thiab solidifies sai nyob rau hauv lub siab kom tau lub casting. Txawm li cas los xij, raws li cov yam ntxwv ntawm cov khoom tsim thiab cov txheej txheem tuag casting, tseem muaj qee qhov chaw ntawm cov pob qij txha kub los yog qhov muaj feem cuam tshuam rau huab cua shrinkage qhov hauv cov khoom, uas yog vim:

(1) Kev kub siab casting siv lub siab los nias kua hlau rau hauv pwm kab noj hniav ntawm kev kub ceev. Cov pa roj hauv lub siab chamber lossis pwm kab noj hniav tsis tuaj yeem tso tawm tag nrho. Cov pa roj no koom nrog hauv cov kua hlau thiab nws thiaj li muaj nyob rau hauv lub casting nyob rau hauv daim ntawv ntawm pores.

(2) Lub solubility ntawm cov roj hauv cov kua txhuas thiab cov khoom txhuas txhuas sib txawv. Nyob rau hauv cov txheej txheem solidification, roj yog inevitably precipitated.

(3) Cov kua hlau ua kom muaj zog sai hauv cov kab noj hniav, thiab yog tias tsis muaj kev noj zaub mov zoo, qee qhov ntawm cov casting yuav tsim cov kab noj hniav los yog shrinkage porosity.

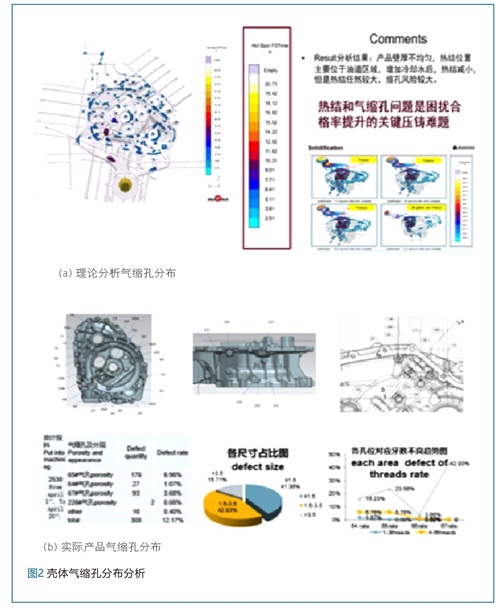

Coj DPT cov khoom lag luam uas tau nkag mus rau hauv cov qauv siv tau zoo thiab cov khoom siv me me raws li qhov piv txwv (saib daim duab 2): Qhov tsis xws luag ntawm qhov pib cua shrinkage qhov ntawm cov khoom raug suav, thiab qhov siab tshaj plaws yog 12.17%, ntawm cov huab cua. shrinkage qhov loj dua 3.5mm suav rau 15.71% ntawm tag nrho cov tsis xws luag, thiab cov cua shrinkage qhov nruab nrab ntawm 1.5-3.5mm suav rau 42.93%. Cov huab cua shrinkage qhov no feem ntau yog concentrated nyob rau hauv ib co threaded qhov thiab sealing nto. Cov yam tsis xws luag no yuav cuam tshuam rau lub qhov kev sib txuas tau sib txuas lub zog, qhov chaw saum npoo thiab lwm yam kev ua haujlwm ntawm cov kev xav tau ntawm seem.

Txhawm rau daws cov teeb meem no, cov txheej txheem tseem ceeb yog raws li hauv qab no:

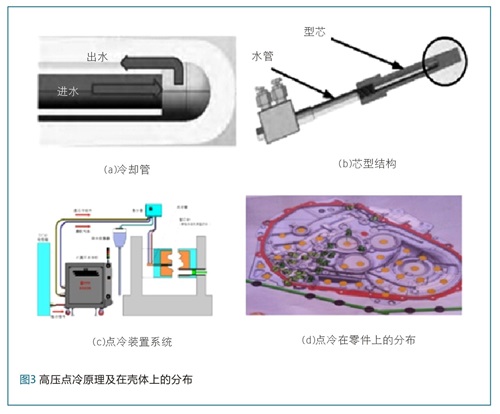

2.1SPOT COOLING SYSTEM

Haum rau ib qho sib sib zog nqus kab noj hniav thiab cov tub ntxhais loj. Kev tsim ib feem ntawm cov qauv no tsuas muaj ob peb qhov sib sib zog nqus kab noj hniav los yog cov kab noj hniav sib sib zog nqus ntawm cov tub ntxhais rub, thiab lwm yam, thiab ob peb cov pwm yog qhwv los ntawm cov kua txhuas loj, uas yooj yim ua rau overheating ntawm pwm, ua rau nplaum. pwm lim, kub tawg thiab lwm yam tsis xws luag. Yog li ntawd, nws yog ib qho tsim nyog yuav tsum tau ua kom cov dej txias txias ntawm qhov chaw ntawm qhov sib sib zog nqus kab noj hniav pwm. Sab hauv ntawm cov tub ntxhais nrog ib txoj kab uas hla ntau dua 4 hli yog txias los ntawm 1.0-1.5mpa dej siab, thiaj li xyuas kom meej tias cov dej txias txias yog txias thiab kub, thiab cov ntaub so ntswg nyob ib puag ncig ntawm cov tub ntxhais tuaj yeem ua ntej khov thiab tsim ib qho. tuab txheej, thiaj li yuav txo tau lub shrinkage thiab porosity nyiam.

Raws li pom nyob rau hauv daim duab 3, ua ke nrog cov ntaub ntawv txheeb xyuas cov ntaub ntawv ntawm simulation thiab cov khoom siv tiag tiag, qhov kawg taw tes txias layout tau optimized, thiab lub siab-siab point txias raws li qhia nyob rau hauv daim duab 3 (d) tau teem rau pwm, uas zoo tswj. cov khoom kub nyob rau hauv lub kub sib koom cheeb tsam, pom tau hais tias tus sequential solidification ntawm cov khoom, zoo txo cov tiam ntawm shrinkage qhov, thiab ua kom tus nqi tsim nyog.

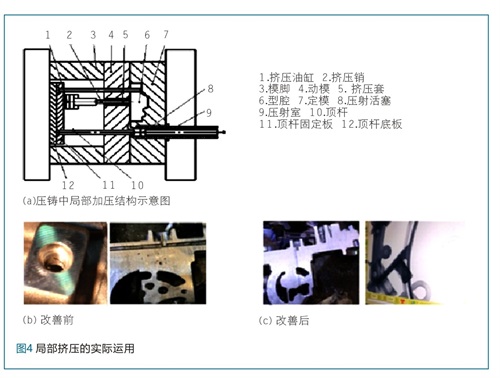

2.2Hauv zos extrusion

Yog tias cov phab ntsa tuab ntawm cov khoom tsim qauv tsis sib xws lossis muaj cov kub kub loj hauv qee qhov chaw, qhov shrinkage yog nquag tshwm sim nyob rau hauv qhov kawg solidified ib feem, raws li qhia nyob rau hauv FIG. 4 (C) hauv qab no. Lub qhov shrinkage nyob rau hauv cov khoom no tsis tuaj yeem tiv thaiv los ntawm kev tuag casting txheej txheem thiab ua kom txias txoj kev. Nyob rau lub sijhawm no, lub zos extrusion tuaj yeem siv los daws qhov teeb meem. Ib feem ntawm cov qauv siab raws li pom nyob rau hauv daim duab 4 (a), uas yog ntsia ncaj qha rau hauv pwm lub tog raj kheej, tom qab cov hlau molten ntim rau hauv pwm thiab solidified ua ntej, tsis tag rau hauv cov khoom semi-solid hlau kua hauv kab noj hniav, thaum kawg. solidification tuab phab ntsa los ntawm extrusion pas nrig siab yuam pub noj kom txo los yog tshem tawm nws cov shrinkage kab noj hniav tsis xws luag, thiaj li yuav tau txais zoo ntawm tuag casting.

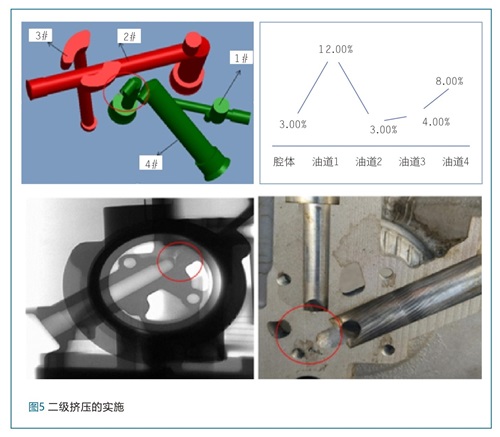

2.3Qhov thib ob extrusion

Qhov thib ob theem ntawm extrusion yog teem ib lub tog raj kheej ob leeg stroke. Thawj qhov mob stroke ua tiav ib nrab molding ntawm qhov pib pre-casting qhov, thiab thaum cov kua txhuas nyob ib ncig ntawm cov tub ntxhais yog maj mam solidified, qhov thib ob extrusion txiav txim yog pib, thiab cov nyhuv ob zaug ntawm pre-casting thiab extrusion yog thaum kawg paub. Siv lub gearbox vaj tse ua piv txwv, qhov tsim nyog tus nqi ntawm kev ntsuas roj-nruj ntawm lub gearbox vaj tse nyob rau hauv thawj theem ntawm qhov project yog tsawg dua 70%. Kev faib tawm ntawm cov dej xau feem ntau yog kev sib tshuam ntawm cov roj hla 1 # thiab cov roj hla 4 # (lub voj voog liab hauv daim duab 5) raws li qhia hauv qab no.

2.4CASTING RUNNER SYSTEM

Cov txheej txheem casting ntawm cov hlau tuag casting pwm yog cov channel uas ua rau cov kab noj hniav tuag casting qauv nrog cov kua hlau molten hauv cov xovxwm chamber ntawm lub tshuab tuag casting nyob rau hauv qhov kub thiab txias, kev kub ceev thiab kev kub ceev. Nws suav nrog kev khiav ncaj nraim, tus neeg sib tw khiav, sab hauv kev khiav thiab cov dej ntws tawm. Lawv raug coj mus rau hauv cov txheej txheem ntawm cov kua hlau filling kab noj hniav, lub xeev ntws, tshaj tawm thiab siab ntawm cov kua hlau hloov, cov nyhuv ntawm cov pa thiab tuag pwm plays ib qho tseem ceeb nyob rau hauv xws li cov thermal equilibrium xeev ntawm kev tswj thiab kev tswj, yog li ntawd. , gating system txiav txim siab tuag casting nto zoo raws li qhov tseem ceeb ntawm lub xeev microstructure. Kev tsim thiab kev ua tiav ntawm cov txheej txheem pouring yuav tsum yog raws li kev sib xyaw ntawm kev xav thiab kev coj ua.

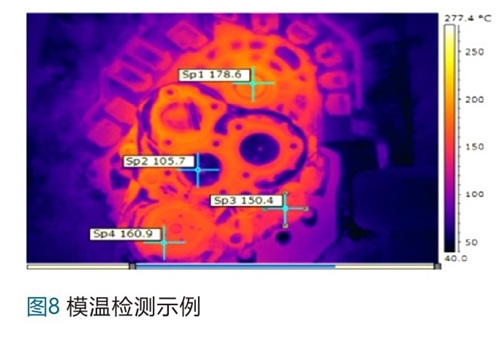

2.5ProcessOptimization

Cov txheej txheem tuag casting yog txheej txheem kub txheej txheem uas ua ke thiab siv lub tshuab tuag casting, tuag casting tuag thiab kua hlau raws li cov txheej txheem ua ntej xaiv thiab cov txheej txheem tsis raug, thiab tau txais qhov tuag casting nrog kev pab ntawm lub zog tsav. Nws yuav siv txhua yam hauv kev xav, xws li lub siab (xws li kev txhaj tshuaj, kev txhaj tshuaj tshwj xeeb, kev nthuav dav, pwm xauv quab yuam), kev txhaj tshuaj nrawm (nrog rau kev nrawm nrawm, lub rooj vag sab hauv, thiab lwm yam), Kev ntim ceev, thiab lwm yam) , ntau yam kub (melting kub ntawm cov kua hlau, tuag casting kub, pwm kub, thiab lwm yam), ntau lub sij hawm (sau lub sij hawm, siab tuav lub sij hawm, pwm tuav lub sij hawm, thiab lwm yam), thermal zog ntawm pwm (kub hloov pauv tus nqi, tshav kub. muaj peev xwm tus nqi, kub gradient, thiab lwm yam.), casting zog thiab thermal zog ntawm cov kua hlau, thiab lwm yam. Qhov no plays lub luag hauj lwm nyob rau hauv lub tuag casting siab, filling ceev, filling cov yam ntxwv thiab thermal zog ntawm pwm.

2.6Kev siv cov txheej txheem tshiab

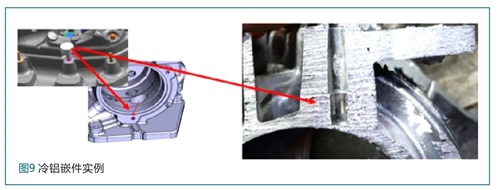

Txhawm rau kom daws tau qhov teeb meem ntawm qhov xoob xoob hauv qhov tshwj xeeb ntawm lub plhaub gearbox, cov kev daws teeb meem ntawm cov khoom siv txias txias tau siv cov tho kev tom qab kev pom zoo los ntawm ob qho tib si cov khoom siv thiab kev xav tau. Ntawd yog, ib qho txhuas thaiv yog loaded rau hauv cov khoom ua ntej filling, raws li qhia nyob rau hauv daim duab 9. Tom qab sau thiab solidification, qhov ntxig no tseem nyob rau hauv qhov chaw los daws qhov teeb meem ntawm lub zos shrinkage thiab porosity.

Post lub sij hawm: Sep-08-2022