Kev kub siab tuag casting yog ib txoj kev uas ua rau cov kua los yog ib nrab-kua hlau sau cov kab noj hniav ntawm tuag casting pwm ntawm qhov kub ceev nrog kev kub siab, thiab cov ntaub ntawv thiab solidifies nyob rau hauv siab kom tau lub casting.

1. Kev kub siab casting txheej txheem

1.1

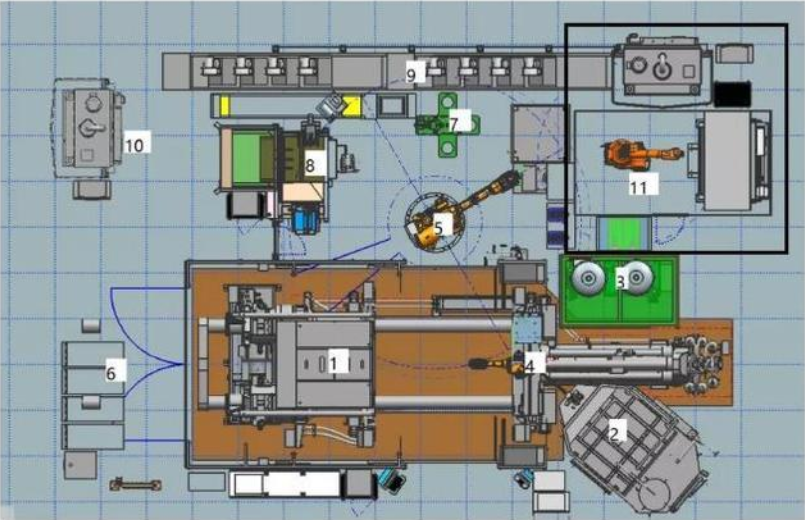

Tam sim no, cov kob tuag-casting dav dav yuav xav txog cov kev teeb tsa hauv qab no; Die-casting tshuab nrog lub tshuab nqus tsev, qhov cub txuag hluav taws xob yog nruab nrog ntau qhov system casting, cov khoom siv nrog cov txheej txheem txau, txo lub sij hawm txau, cov neeg hlau coj mus rau qhov chaw, lub hnab slag, code txiav thiab lwm yam haujlwm, qhov kawg txiav mus rau qhov rooj vag system; Cov kob tuag-casting kuj tuaj yeem hloov kho rau kev tu lub tshuab ua haujlwm nyob rau hauv cov khoom ntim siab.

1.2

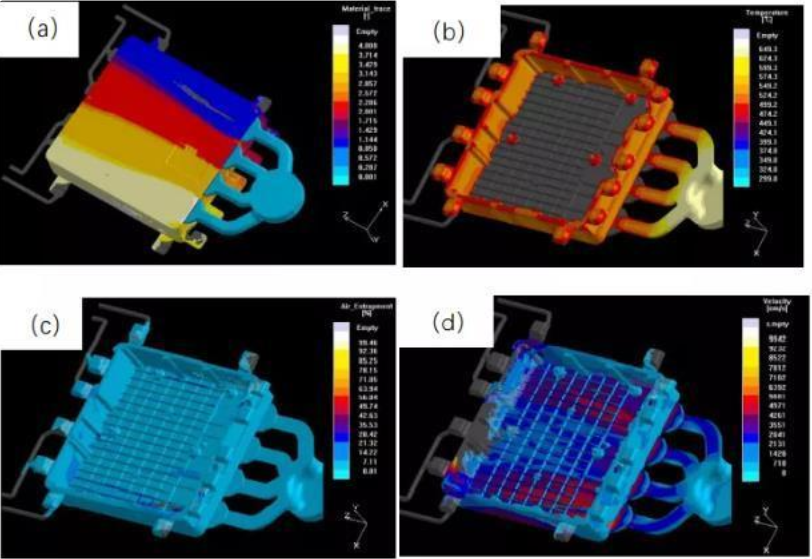

CAE tsom xam yog ntau thiab ntau lug siv nyob rau hauv tuag casting kev lag luam, sawv cev los ntawm PROCAST, MAGMA, ntws-3D, thiab lwm yam. tsis zoo filling, uas zoo heev txhim kho cov txiaj ntsig thiab txuag tau tus nqi zoo heev. Nws yog ib qho tseem ceeb heev uas yuav tau sai thiab scientific tsim tag nrho casting system (lub rooj vag, sprue thiab overflow tank, thiab lwm yam) rau tuag casting. Optimize casting txheej txheem tsis, txo tus naj npawb ntawm cov pwm kuaj, txo tus nqi casting, txhim kho cov khoom zoo. CAE software tau siv rau kev tshuaj xyuas dav dav ntawm kev sau, kev sib koom ua ke, porosity faib thiab tshaj tawm cov ntaub ntawv xa tawm

1.3 Kev siv lub tshuab nqus tsev tuag casting

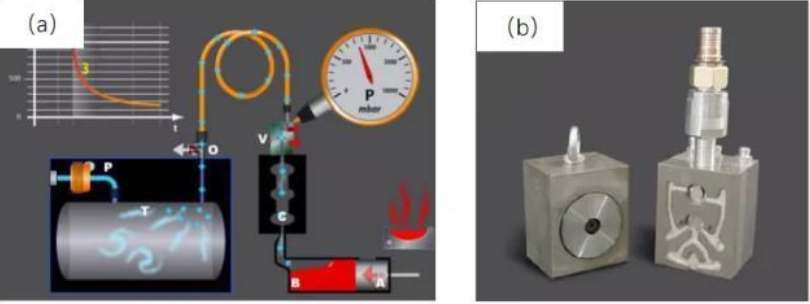

Nrog rau cov khoom lag luam kom zoo, kev siv lub tshuab nqus tsev los daws qhov teeb meem ntawm kev txhaws thiab cua nruj ntawm cov castings tau tsim tau zoo, thiab lub tshuab nqus tsev feem ntau siv, feem ntau siv lub tshuab nqus tsev vacuum muaj ob lub qauv hauv qab no. Daim duab 3 yog daim duab schematic ntawm lub tshuab nqus tsev vacuum. Zoo li cov txheej txheem tuag casting zoo tib yam, tom qab cov dej txhuas nkag mus rau hauv chamber, lub tshuab nqus tsev pib pib. Tom qab ntawd, thaum lub tshuab tuag casting pib ntawm kev kub ceev, lub zog kinetic ntawm txhuas dej yog tso siab rau kov lub caij nplooj ntoos hlav phaj ntawm lub tshuab nqus tsev valve. Thaum siv lub tshuab nqus tsev vacuum, nws feem ntau kaw thaum preheating pwm. Thaum lub preheating tiav lawm, lub tshuab nqus tsev valve yuav siv tau tsuas yog thaum lub siab ceev thiab pressurization pib. Cov tshuab nqus tsev vacuum muaj qhov zoo ntawm kev siv yooj yim, tab sis kev ua tiav ntawm lub tshuab nqus tsev vacuum yog siab, thiab tus nqi ntawm lub tshuab nqus tsev vacuum yog qhov siab. Daim duab 4 yog daim duab schematic ntawm lub tshuab nqus tsev hydraulic. Lub hauv paus ntsiab lus ntawm lub tshuab nqus tsev vacuum yog tib yam. Thaum lub punch pib, lub tshuab nqus tsev pib, tab sis lub hauv paus ntsiab lus ntawm kev kaw lub tshuab nqus tsev vacuum yog txawv. Thaum lub tshuab nqus tsev hydraulic feem ntau pib ntawm kev kub ceev, hom xa mus rau hydraulic system ntawm lub tshuab nqus tsev vacuum tib lub sijhawm, thiab lub tshuab nqus tsev vacuum kaw. Tus nqi ntawm hydraulic lub tshuab nqus tsev vacuum yog qhov tsawg, tab sis nws yuav tsum tau ua kom cov txheej txheem tuag casting tsis thiab pwm tsim yuav tsum sib phim, txwv tsis pub cov txhuas dej tuag casting rau hauv lub tshuab nqus tsev yuav ua rau txhaws.

2. Castings

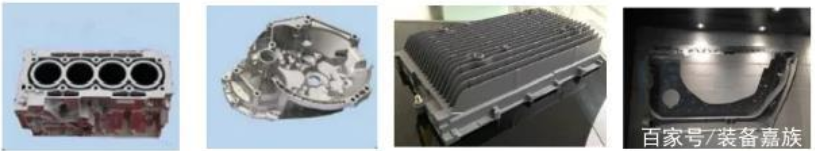

Tam sim no, aluminium alloy tuag casting khoom tau muab faib ua peb pawg raws li tus nqi. Thawj qeb yog tsheb, maus taus, lub plhaub kis tau tus mob uas sawv cev los ntawm lub cav cav, lub tog raj kheej lub cev thiab lwm yam. Hom thib ob yog lub hauv paus chaw nres tsheb plhaub thiab lub plhaub lim uas sawv cev los ntawm kev sib txuas lus hauv network, thiab hom thib peb yog lub cev qauv nrog kev ua haujlwm zoo dua qub. Raws li pom nyob rau hauv daim duab, nws yog ib tug raug txhuas alloy tuag casting khoom:

3. Cov lus xaus

Aluminium alloy muaj lub zog tshwj xeeb thiab zoo corrosion kuj, zoo heev hluav taws xob conductivity. Raws li kev sib raug zoo ntawm kev txuag hluav taws xob thiab kev txo qis qis thiab kev tiv thaiv ib puag ncig ntsuab, aluminium alloy tuag casting tau tsim sai heev hauv Suav teb. Kuv ntseeg hais tias nyob rau hauv lub neej yav tom ntej, aluminium alloy khoom yuav muaj ntau haiv neeg. Lub ntsiab deformation yog nyob rau hauv cov nram qab no yam; 1) Nrog rau kev txhim kho cov khoom, nws yuav tsav txoj kev loj hlob ntawm cov tshiab tuag cam khwb cia txhuas alloy cov ntaub ntawv, xws li: siab thermal conductivity, siab zog thiab siab toughness kev taw qhia; 2) tshiab tuag casting txhuas alloy cov ntaub ntawv kuj tseem yuav tsav txoj kev loj hlob ntawm cov tshiab tuag casting tshuab, xws li semi-tawv tuag casting txheej txheem, lub siab nqus nqus casting 3) technology kev loj hlob kuj yuav muab cov cuab yeej, auxiliary cov ntaub ntawv tso rau pem hauv ntej siab dua cov kev cai. , xws li: loj tuag casting, tuag kub tshuab, txau cov cuab yeej, pwm tso lub cav sib xws, tshuab nqus tsev, txias tshuab, pwm kub tswj thiab nrhiav kom tau qhov system, thiab lwm yam.

Post lub sij hawm: May-19-2022